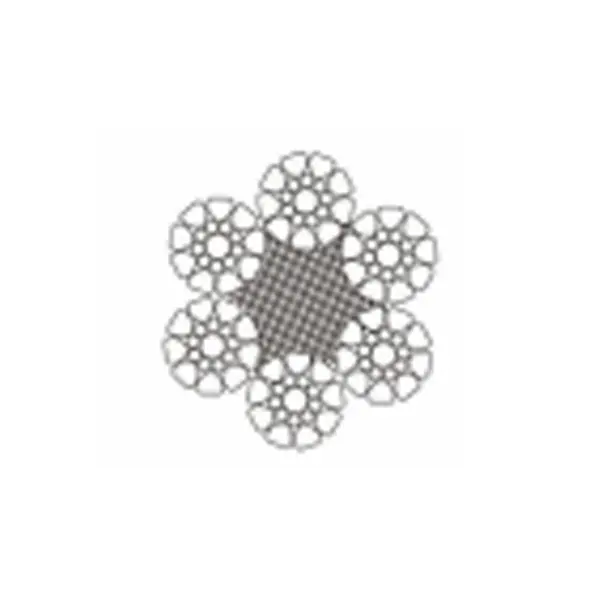

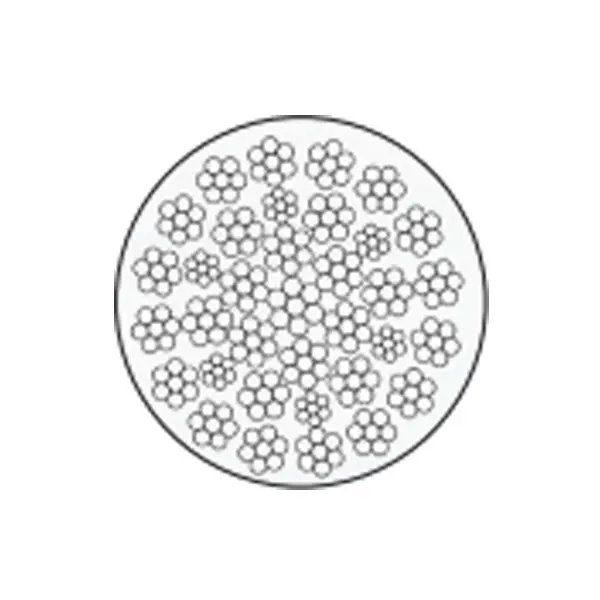

Coated Wire Rope

Plastic-coated steel wire rope is a high-performance lifting and handling tool widely used in various industrial fields.The wire ropes can be coated withTPU PP, PE, PVC, Nylon.Coating various diameter and all kinds of colour according to your request.

Precautions:

1.During transportation and storage, handle coated wire ropes with care to avoid damaging the coating. Store them in a dry, cool place to prevent degradation of the coating.

2.Conduct regular inspections to check for signs of wear, corrosion, or damage to the coating. Pay attention to areas where the rope is in contact with other surfaces, as this is where wear is most likely to occur.

3.Clean the rope regularly to remove dirt and debris that could cause wear or damage to the coating. Avoid using harsh chemicals that could degrade the coating.

4.Never exceed the rated breaking strength of the wire rope. Overloading can cause the coating to crack or peel, reducing its effectiveness.

5.Ensure that the coating material is compatible with the environment in which the rope will be used. For example, PVC coatings are suitable for general outdoor use, while nylon coatings may be preferred for applications with higher abrasion.

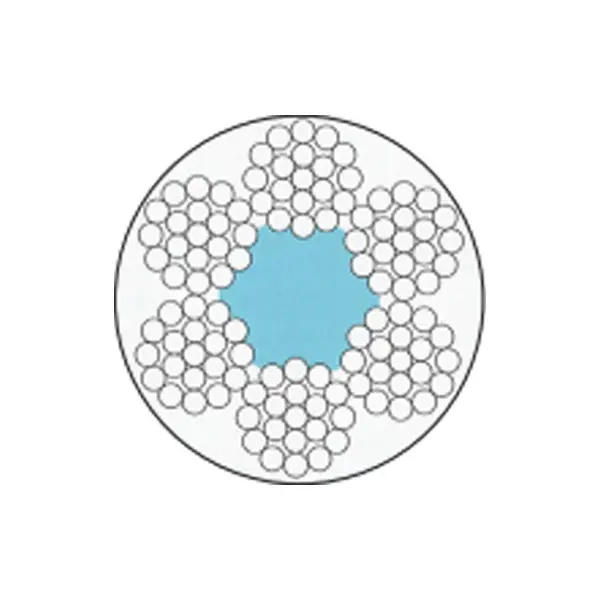

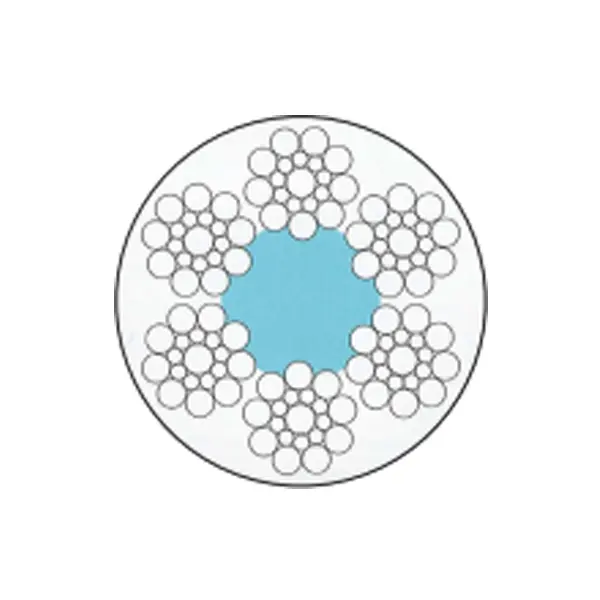

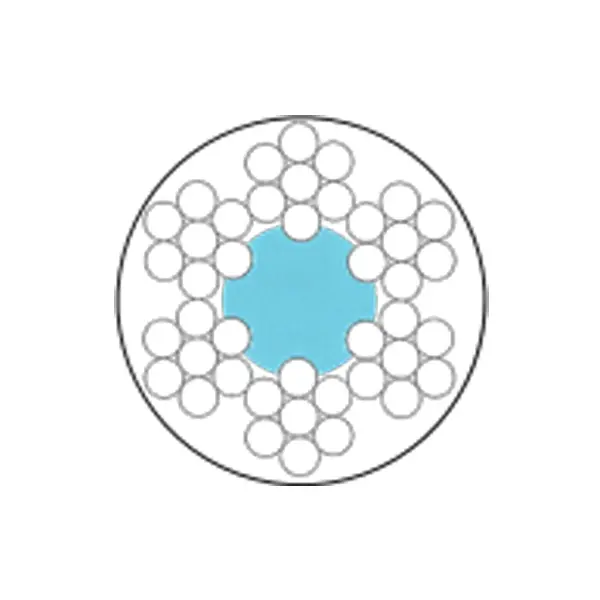

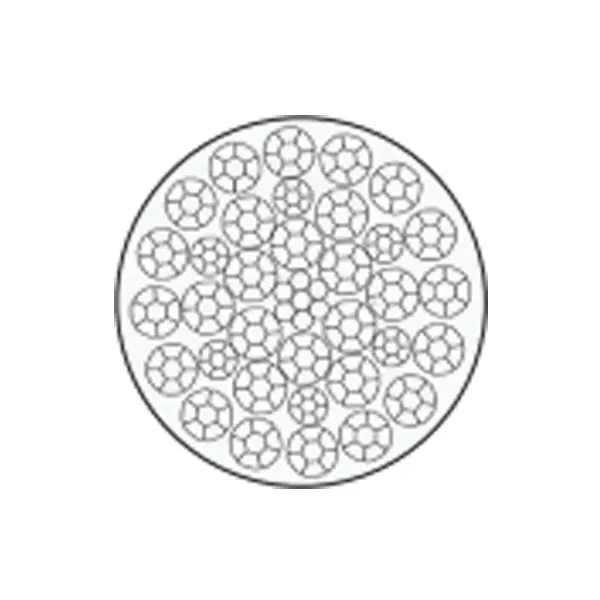

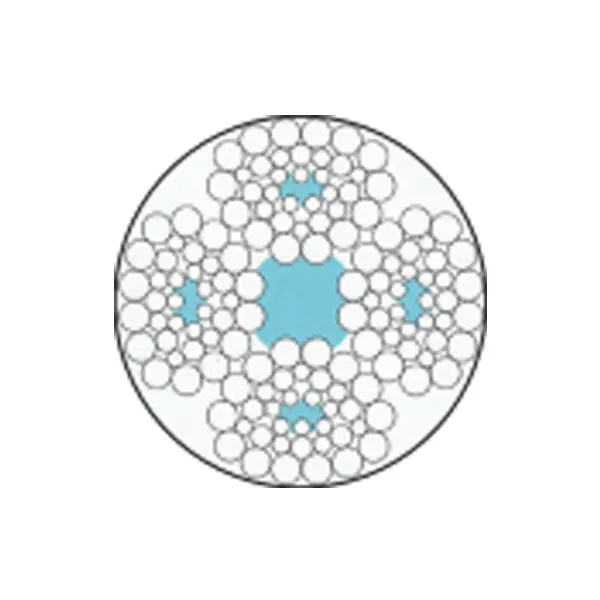

Galvanized Steel Wire Rope

Galvanized steel wire ropes are made offine Carbon Steel Wire, There are Hot dip galvanized and Electric Galvanized wire rope,The galvanized wire ropes have higher tensile strength and better oxidation resistance than ungalvanized. widely used in lifting locks, car control cable, garage door lock, rein forcement cable etc.

Precautions:

1.Avoid dragging the wire rope on abrasive surfaces to prevent damage to the zinc coating. Store in a dry, well-ventilated area to prevent moisture buildup and corrosion.

2.Never exceed the recommended working load limit (WLL) to prevent overloading and potential failure. Ensure the wire rope is suitable for the specific application (e.g., lifting, towing, or rigging).

3.Regularly inspect for signs of wear, corrosion, broken wires, or deformation. Replace the wire rope if it shows significant damage or exceeds the allowable number of broken wires.

4.Use proper fittings, clamps, or end terminations to secure the wire rope. Avoid sharp bends or angles that can cause stress concentrations.

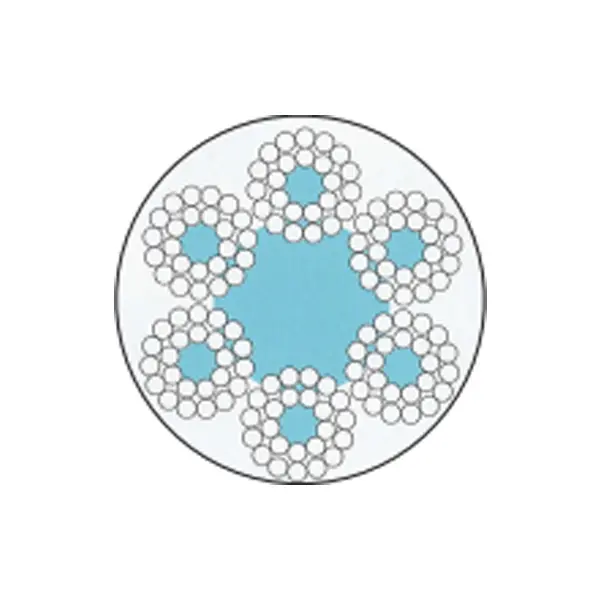

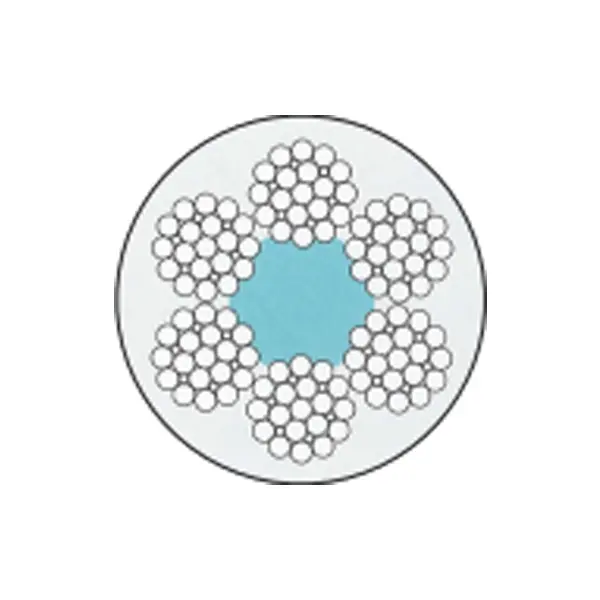

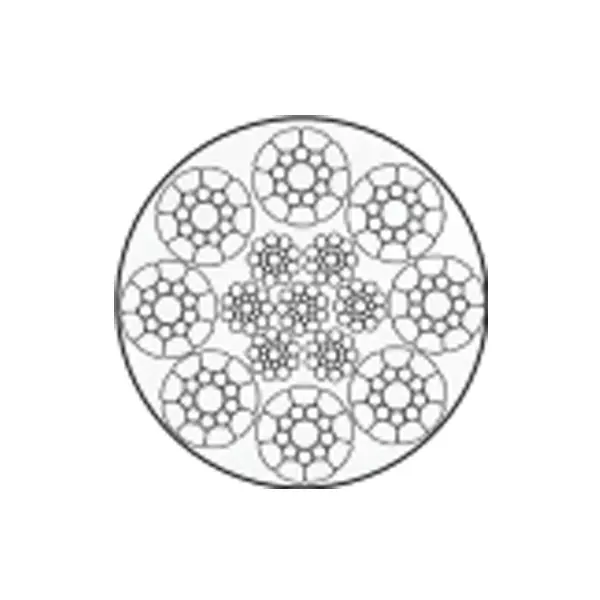

Stainless Steel Wire Rope

Stainless steel wire rope is made of high quality AISI304, AISI316 and other grades of stain less steel. It has excellent corrosion resistance, high temperature resistance and low temperature resistance.It is widely used in petrochemical industry.aviation, automobile, fishery. precision instruments and Building decoration and other industries.After the stainless steel wire rope is electropolished, the surface is brighter and the corrosion resistance is greatly increased. After low temperature treatment, the wire rope can achieve higher strength.

Precautions:

1.Never exceed the rated breaking strength of the wire rope. Always use appropriate safety factors (typically 5 or higher) to ensure the rope is not subjected to loads close to its breaking strength.

2.Ensure the wire rope is installed correctly to avoid kinks and sharp bends, which can weaken the rope. Use sheaves and drums with appropriate diameters to minimize bending stresses.

3.Conduct regular visual inspections to check for signs of wear, corrosion, broken wires, or deformation. Inspect areas where the rope contacts sheaves, drums, or other hardware.

4.Store stainless steel wire ropes in a dry, cool, and well-ventilated area to prevent corrosion. Avoid storing them in damp or humid environments.