Thread Lift Loop

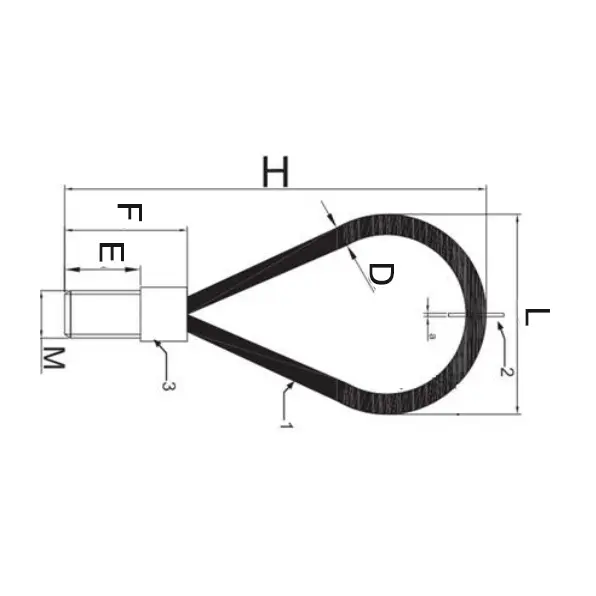

Product Parameters

| Safe load | D | H | L | M | E | F |

| Load(t) | mm | mm | mm | mm | mm | mm |

| 0.5 | 6 | 155 | 60 | 12 | 21 | 32 |

| 0.8 | 7 | 155 | 60 | 14 | 24 | 35 |

| 1.2 | 8 | 165 | 60 | 16 | 26 | 41 |

| 1.6 | 9 | 190 | 70 | 18 | 33 | 48 |

| 2 | 10 | 215 | 90 | 20 | 34 | 49 |

| 2.5 | 12 | 255 | 100 | 24 | 42 | 59 |

| 4 | 16 | 300 | 120 | 30 | 54 | 74 |

| 6.3 | 18 | 360 | 140 | 36 | 67 | 87 |

| 8 | 20 | 425 | 160 | 42 | 75 | 105 |

| 12.5 | 26 | 530 | 180 | 52 | 95 | 125 |

Product Features

01

7 Jan 2019

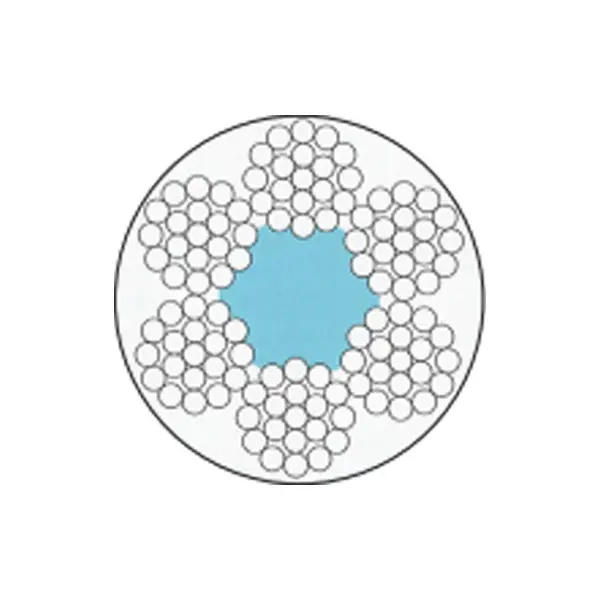

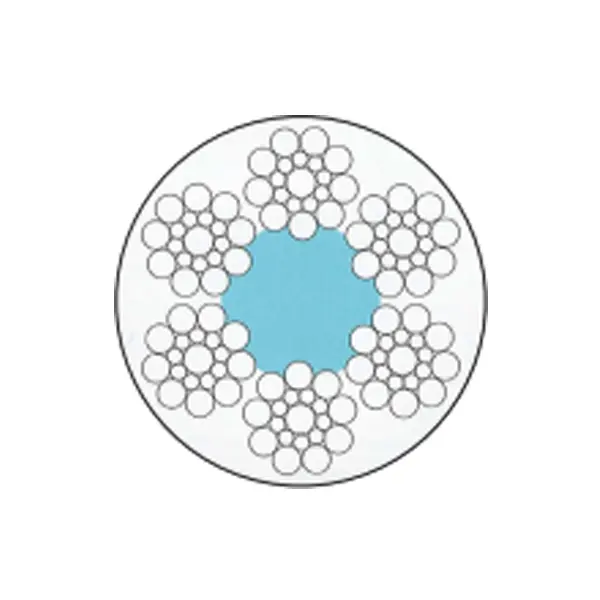

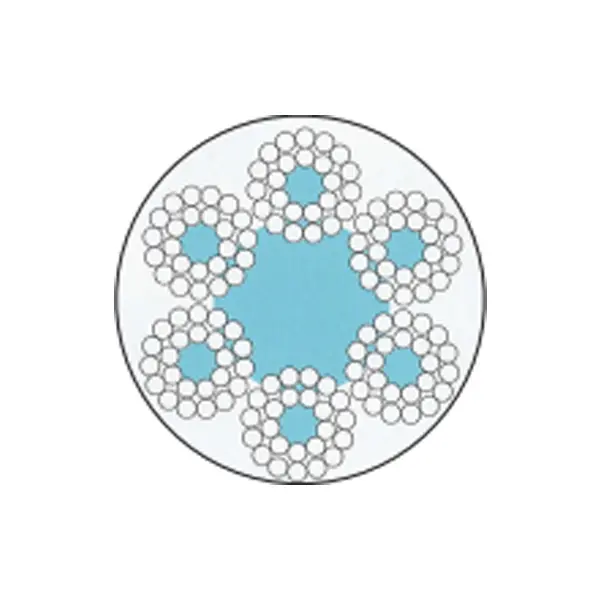

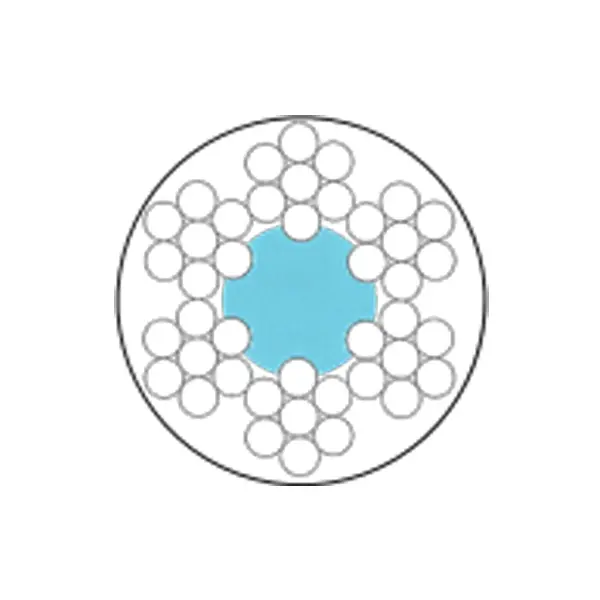

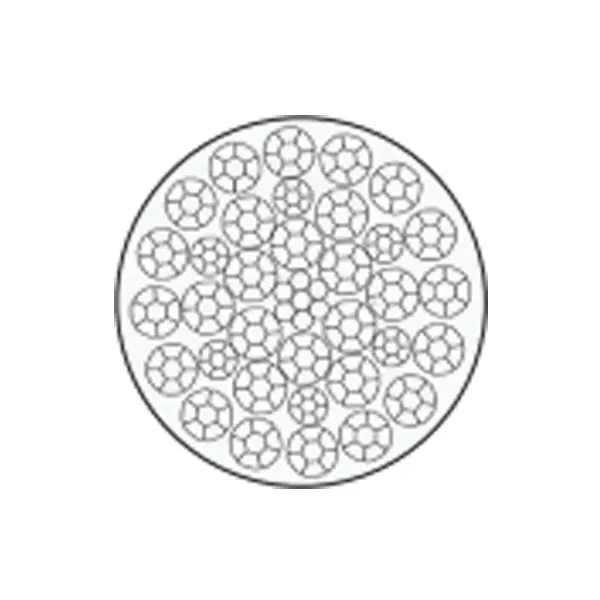

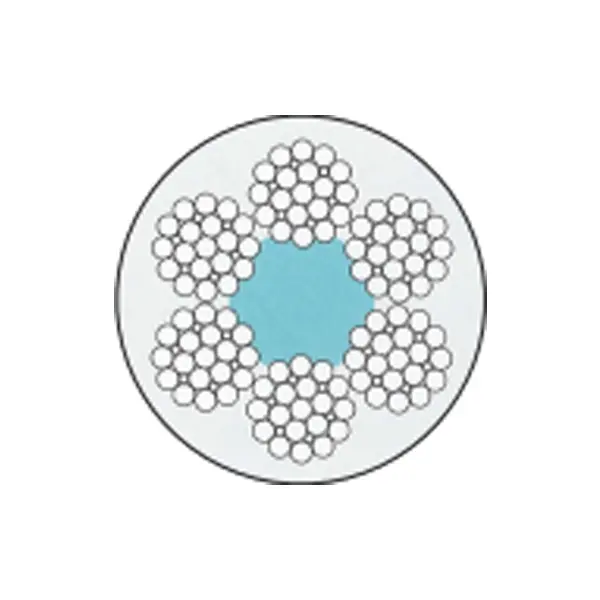

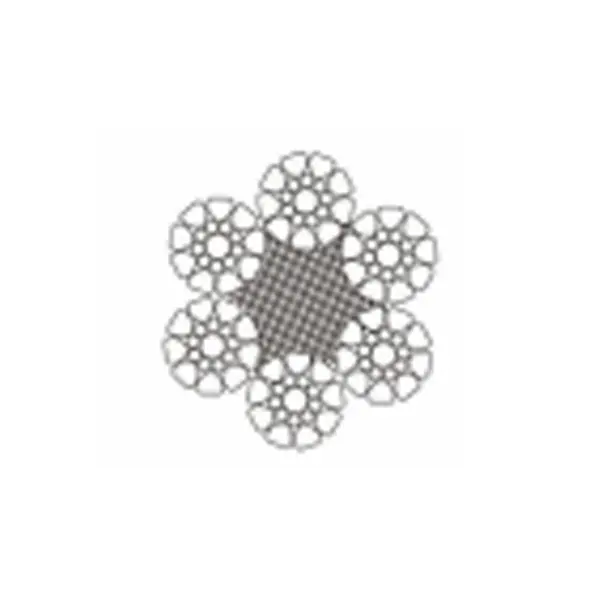

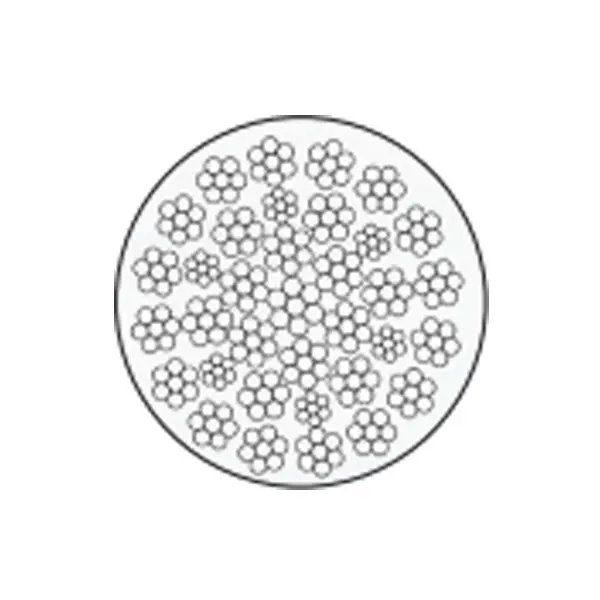

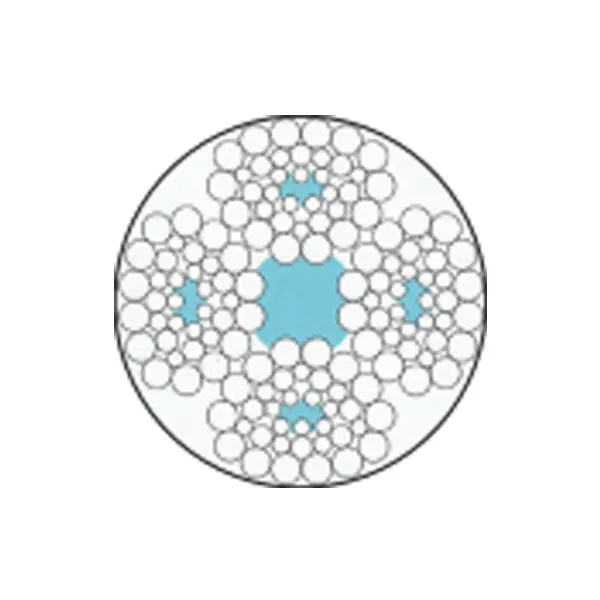

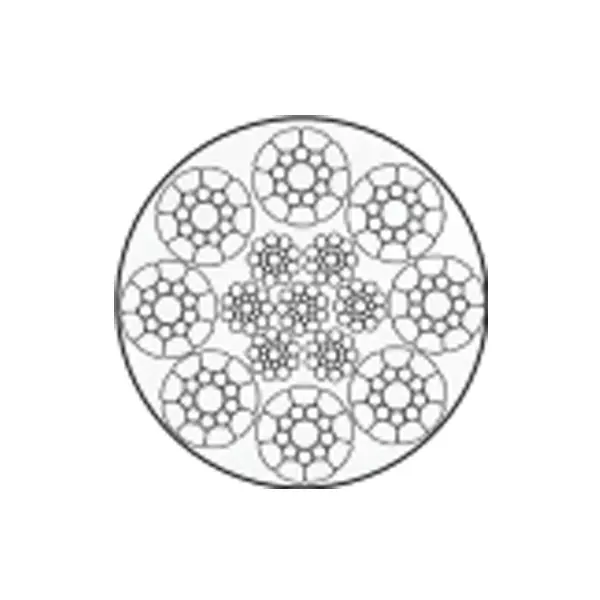

Material and Structure: Threaded lifting slings are usually made from high-strength alloy steel, offering corrosion resistance and wear resistance. Their design includes a threaded end for connecting to lifting equipment (such as cranes) and a connection end for attaching to the object being lifted.

Safety: Made from high-quality materials with precision manufacturing processes, they have high load capacity and durability. With proper installation and use, the connections are firm and reliable, reducing the risk of breakage or slippage.

Versatility: Suitable for various environments and conditions, including indoor and outdoor use, as well as different climate conditions.

Note tips

01

7 Jan 2019

Before use, check whether the thread and wire rope are bent, broken, or need to be scrapped

Angle of lifting loop must be less than 45 degrees

The radius of the hook at the top of the lifting loop must be greater than the diameter of the rope