Suspended Netting for Feeder Lines

Feeder Line Hanging Nets play a crucial role in communication engineering. They provide reliable support and protection for the laying and maintenance of communication lines. In modern communication networks, Feeder Line Hanging Nets are widely used in various scenarios to ensure stable transmission of communication signals.

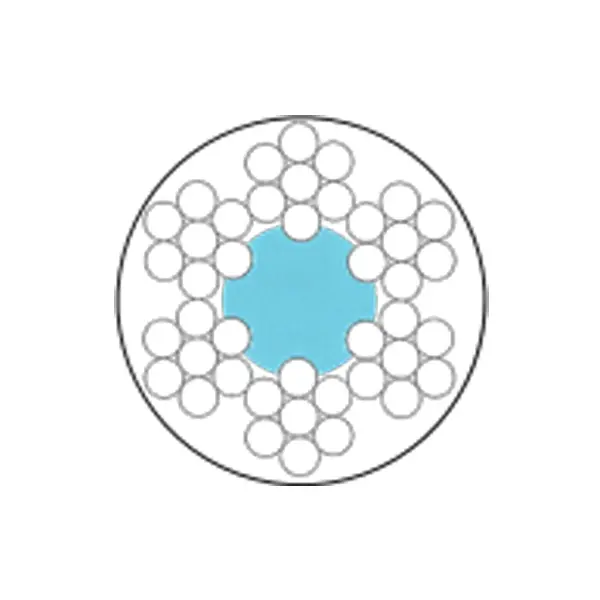

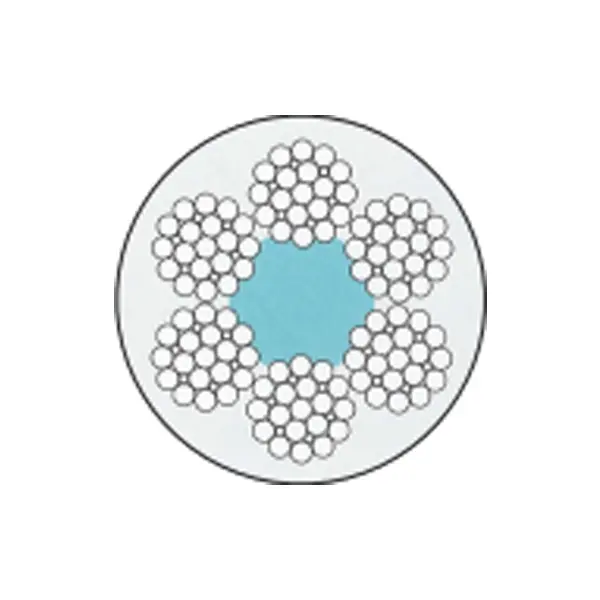

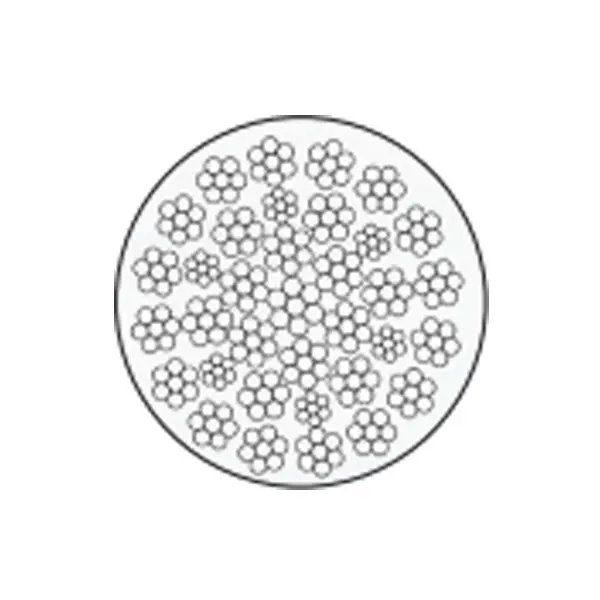

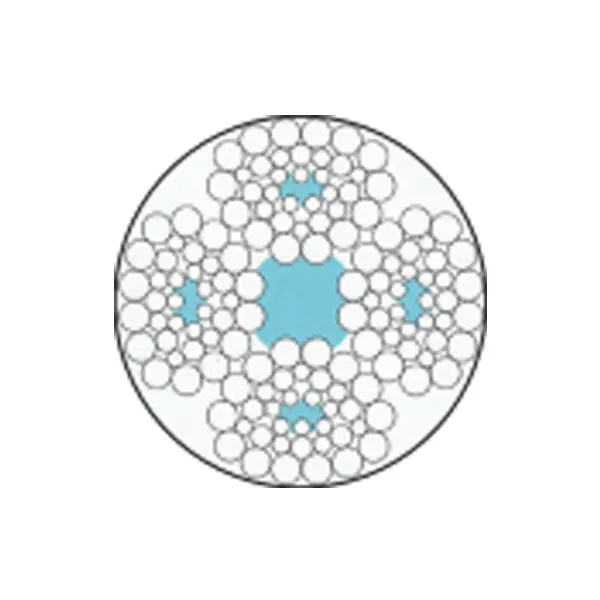

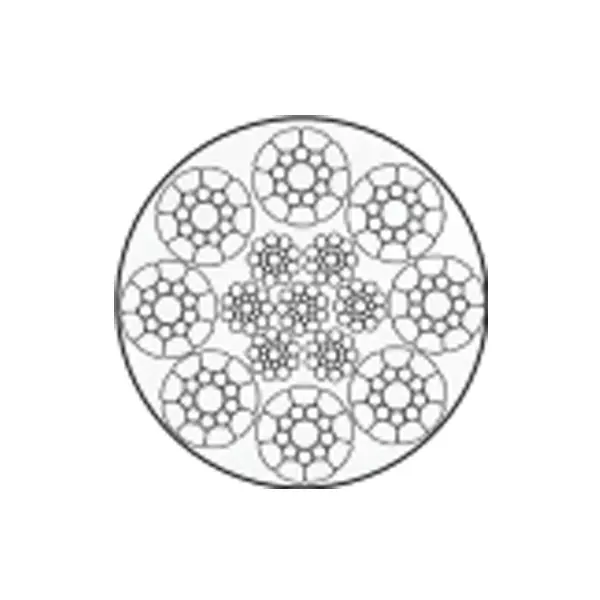

Feeder Line Hanging Nets are usually made of high-strength hot-dip galvanized steel wire rope and stainless steel rope, which have good wear resistance and corrosion resistance. They can withstand heavy loads to ensure the safety of the feeder during lifting. At the same time, the design of the net also considers flexibility and coordination, which can adapt to different installation environments and requirements.

Minitype Rotate Cable Grip Type MX

The Micro Rotating Sleeve MX is a high-performance protection solution specifically designed for small cables and wire harnesses. It combines precision manufacturing technology, durable materials, and a flexible design to provide excellent cable management and protection functions. It is suitable for dragging and pulling small-sized cables and feeders, and its traction head can rotate to release torque.

KT-Style Rotating Cable Grip Mechanism

The Rotating Cable Sleeve KT is a high-performance product specifically designed for cable protection and organization in industrial environments. It combines durable materials, precision manufacturing processes, and user-friendly design to provide an excellent solution for cable management and protection.Using multiple strands hot dip galvanized steel wire rope to weaving, used for cable head draging,it can rotate 360 degrees, release the cable or wire rope torsion.

Double-Head Double-Sided Pull Cable Net Sleeve

The Double-Head Dual-Side Pull Cable Grip (Type RAT) is a high-performance solution designed for the protection and organization of cables, hoses, and pipelines. Made using multiple strands of high-strength silk with a dense mesh weave, it offers durability, stability, and explosion resistance. This versatile grip is ideal for securing and protecting cables, hoses, pipes, and other similar products in demanding environments.

Double Head And Sides Dragging Cable Grip Type RAT

The Double-Head Dual-Side Drawstring Mesh Guard, RAT, is a high-performance tool specifically designed for cable and pipeline protection. It combines robust materials, precision manufacturing processes, and user-friendly design to provide excellent protection and organization solutions.Using multiple strands silk to weave, mesh density,fixed,anti-explosion and protect for cable, hose, pipe and other products.

Cast In Lift Anchor

A Cast-in loop is a circular lifting sling that is partially cast into a concrete component.

The lifting system consists of a circular embedded lifting hook and a recessed mold used to secure the hook to the concrete for lifting purposes.

The exposed area is used for assembly of the lifting hook for hoisting and transportation. After the lifting operation is completed, the exposed portion of the component is cut off and cannot be reused. They are particularly suitable for transporting foundation components, concrete beams, and hollow slabs.

Cast-In Loop/ Cast in Lift Anchor

A Cast-in loop is a circular lifting sling that is partially cast into a concrete component.

The lifting system consists of a circular embedded lifting hook and a recessed mold used to secure the hook to the concrete for lifting purposes.

The exposed area is used for assembly of the lifting hook for hoisting and transportation. After the lifting operation is completed, the exposed portion of the component is cut off and cannot be reused. They are particularly suitable for transporting foundation components, concrete beams, and hollow slabs.

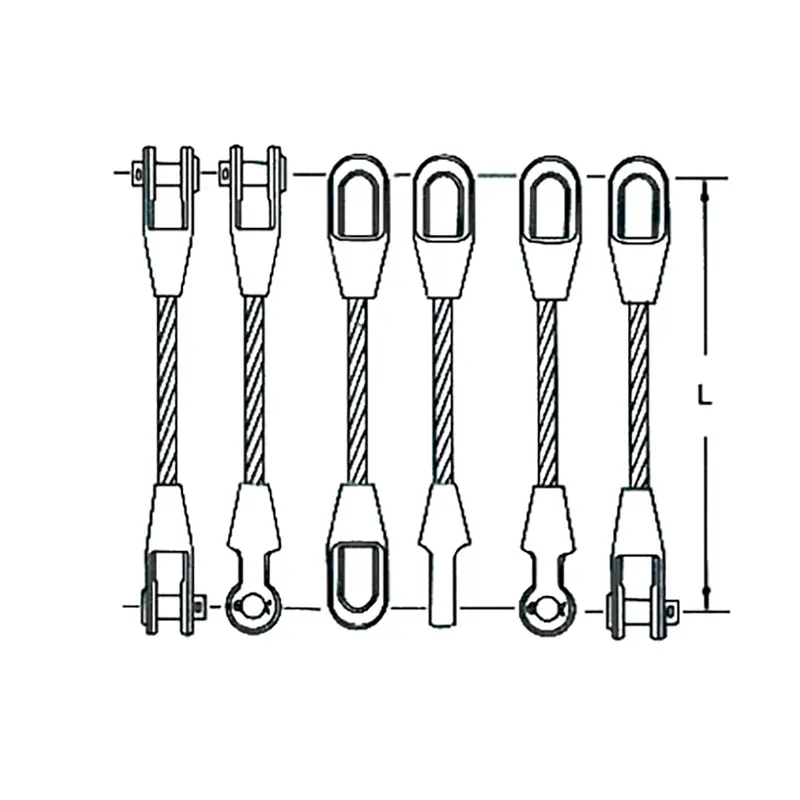

Wire rope pressing sling is a common type of co...

Basic Composition

It consists of steel wire rope and pressed joints. The steel wire rope is the main weight-bearing part, and its material and diameter are determined according to specific needs. The pressed joints are mostly made of metal materials such as aluminum alloy and zinc alloy, and they are connected to the end of the steel wire rope through a pressing process.

Endless Wire Rope Sling

The feature of the endless rope is that the rope body is soft and the lifting points are many, which can solve the operational requirements of small lifting space and high load in various environments, such as transformer, shipbuilding, and special machinery, for the special requirements of large-scale lifting of heavy objects (the warning mark of the endless rope is strictly prohibited from being used as a lifting point).

Thread Lift Loop

Threaded lifting slings are specialized devices used for lifting, dragging, or securing objects.

Loop: Galvanized steel wire rope

Label Identification: plastic or steel

Threaded socket: steel

Precautions:

1.Ensure that the threaded lifting sling is correctly installed and all connections are tightened before use.

2.Regularly check the condition of the threaded lifting sling. If any wear, deformation, or cracks are found, replace it promptly.

3.Do not exceed the rated load capacity of the threaded lifting sling to prevent hazards.

4.When using and storing the threaded lifting sling, keep it dry and clean to avoid contact with oil, chemicals, and other harmful substances.

Open Type Closed Type Casting Sling

Wire rope casting rope joint is a device used to connect the ends of wire ropes and form a reliable fixed connection.

Structural features

- Usually consists of a conical sleeve and casting alloy. The conical sleeve is generally made of metal with a suitable taper, which can accommodate the insertion of the wire rope inside. The casting alloy is mostly zinc-based, aluminium-based and other alloys with good fluidity and strength after solidificatio

Car Trailer Wire Rope Winch

The car towing rope is mainly used for various tow trucks, vehicle towing and rescue, and vehicle transportation.

Material and Structure

Material: It is mainly made of high-strength steel wire wound together. These steel wires are usually treated with special processes to have high tensile strength and can withstand large pulling forces to ensure that they do not break easily in applications of towing vehicle. For example, common high-quality wire rope may use high-strength carbon steel wire, with a tensile strength of several tons or even higher.

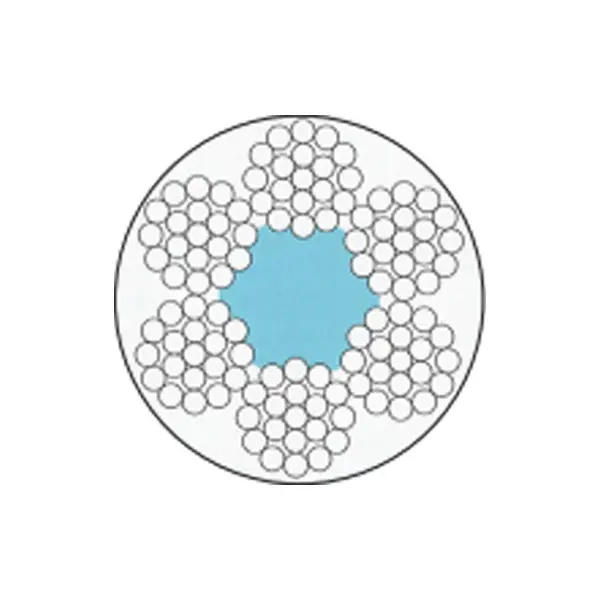

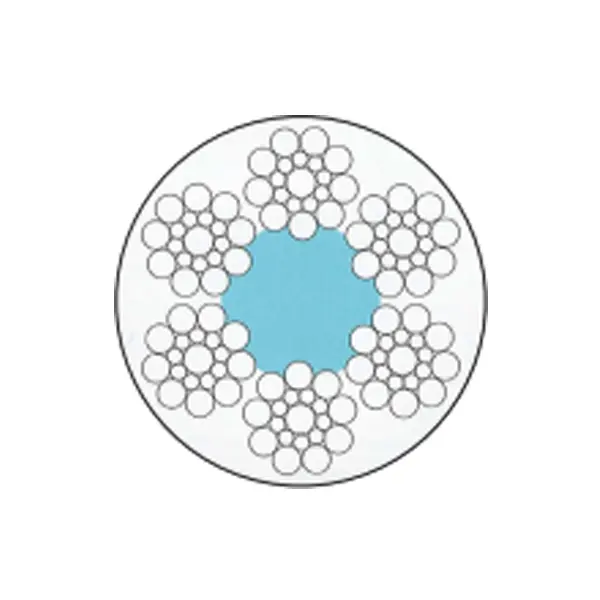

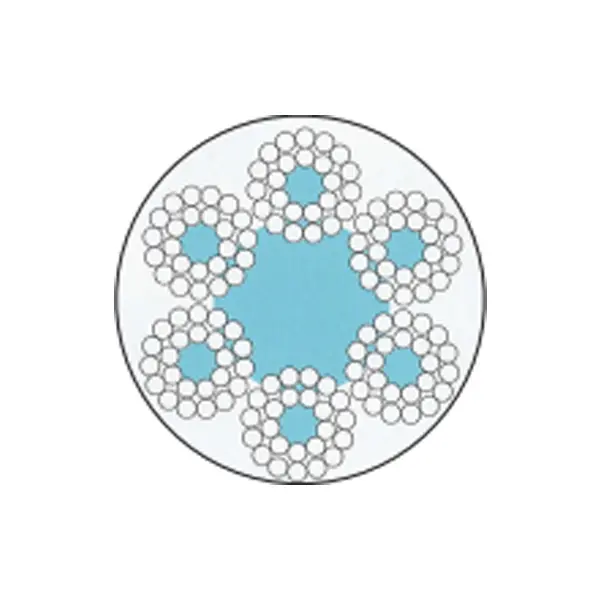

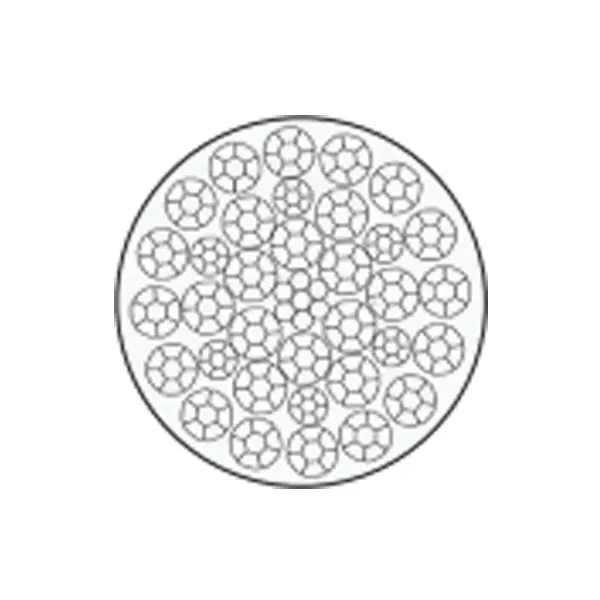

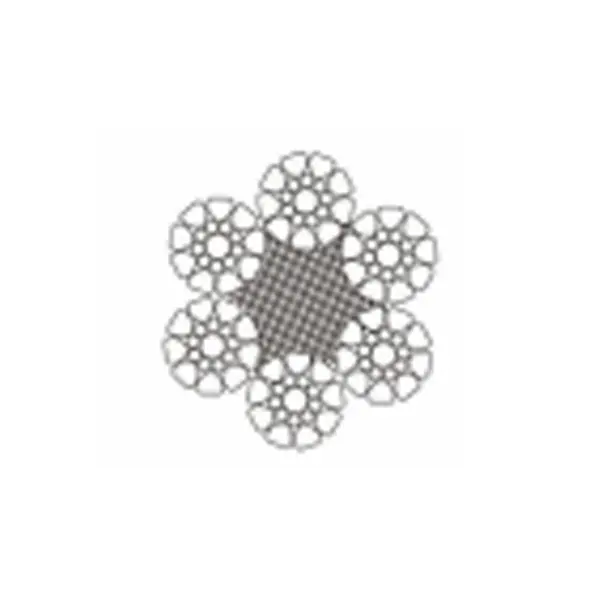

Twisting method: Multiple strands of steel wire are twisted together in a specific way to form the main body of the steel wire rope. Common twisting methods include interlaced twist and parallel twist, and different ways of twisting method can affect the flexibility, strength, etc. of the steel wire rope. Generally, steel wire ropes with interlaced twist are more stable in use, while those with parallel twist have better flexibility.