Change Line Cable Grip Type RB

Product Parameters

Change line cable grip

Mainly used for the replacement of wire rope or cable,when using,one end connected new cable,one end connected old cable,replaced the old cable through the rotation of the crane or hoist.It also can be used for protection cable,hose,pipe and so on.The materials of cable grip can be divided into hot-dip galvanized, stainless steel 304, and stainless steel 316

| Model | Size Range | Total length | Breaking load |

| RB-11 | 8-11 | 1040 | 400 |

| RB-13 | 11-13 | 1210 | 800 |

| RB-16 | 13-16 | 1410 | 800 |

| RB-21 | 16-21 | 1520 | 1100 |

| RB-25 | 21-25 | 1920 | 1300 |

| RB-30 | 25-30 | 2020 | 2100 |

| RB-35 | 30-35 | 2480 | 2400 |

| RB-42 | 35-42 | 2680 | 2800 |

| RB-50 | 42-50 | 3280 | 3300 |

| RB-60 | 50-60 | 3280 | 6000 |

| RB-70 | 60-70 | 2650 | 8000 |

| RB-80 | 70-80 | 3320 | 9000 |

| RB-90 | 80-90 | 3450 | 9000 |

| RB-100 | 90-100 | 3650 | 9000 |

| RB-110 | 100-110 | 3900 | 9600 |

Precautions

01

7 Jan 2019

Use and Operation

To ensure proper use:

1.Install the net sleeve correctly on the cable.

2.Evenly unfold the net sleeve and gently slip it over the cable to avoid deformation or damage.

3.Maintain a uniform pulling force and stable direction during use to prevent cable swaying or twisting.

4.Keep the net sleeve away from sharp objects to prevent scratching the steel wire.

01

7 Jan 2019

Inspection and Maintenance

Regular inspection is crucial for safe and reliable use:

1.Before each use, check for broken, worn, or deformed wires.

2.Assess the impact of minor damage and replace severely damaged sleeves immediately.

3.Stop operation if unusual jams or increased resistance are noticed, and inspect the net sleeve.

4.Conduct thorough inspections and maintenance after a certain number of uses, even if there are no obvious signs of damage.

Product Features

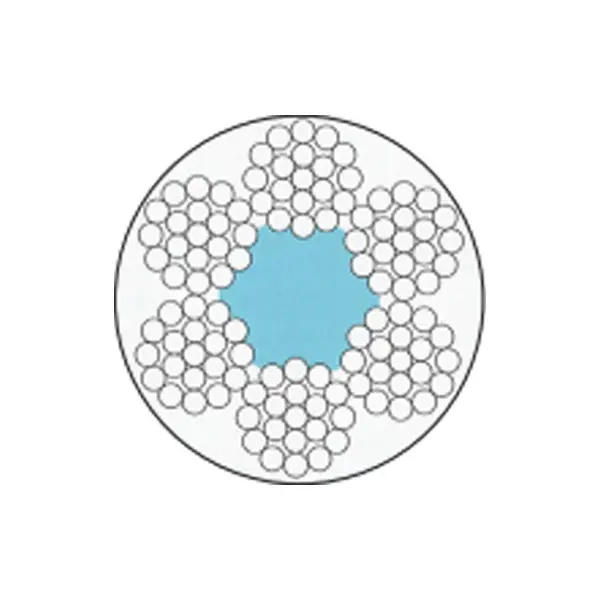

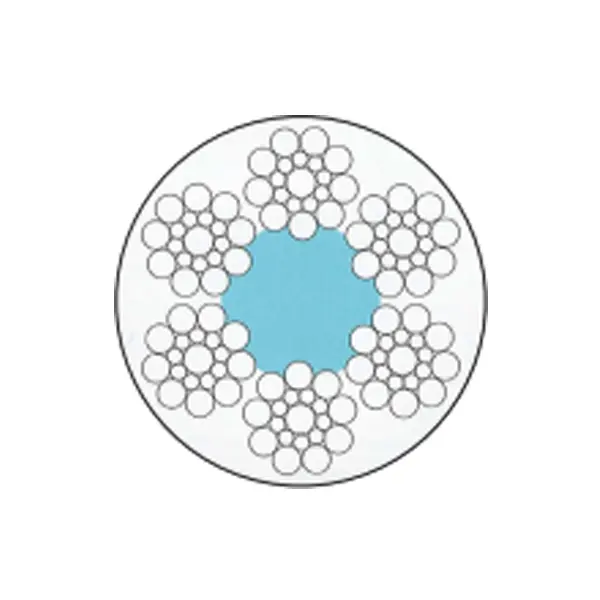

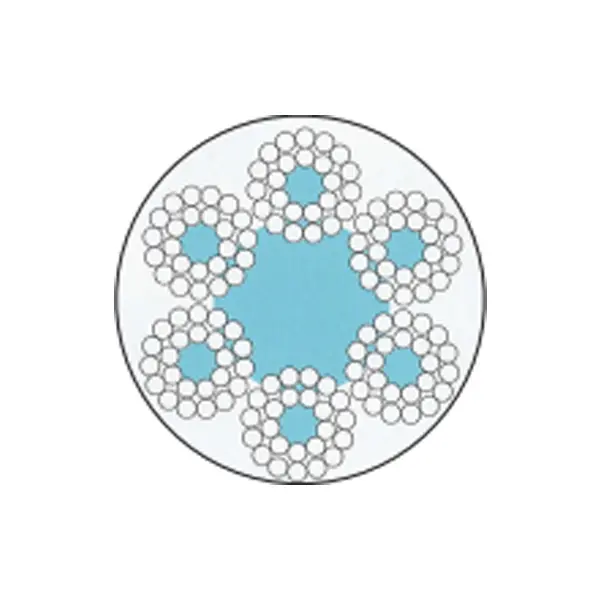

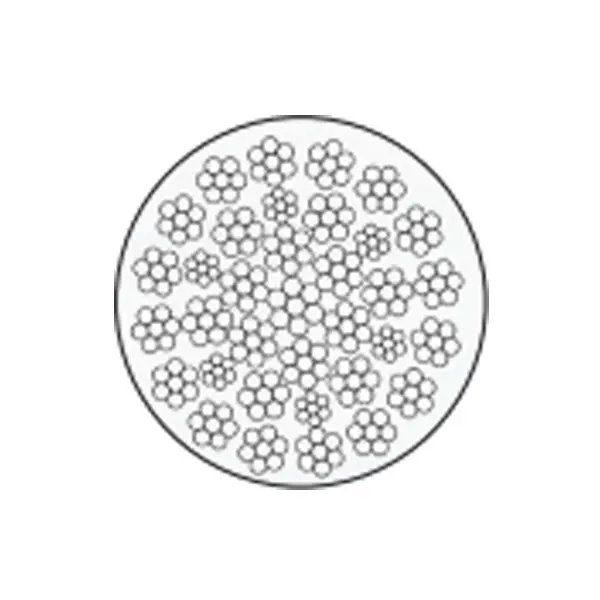

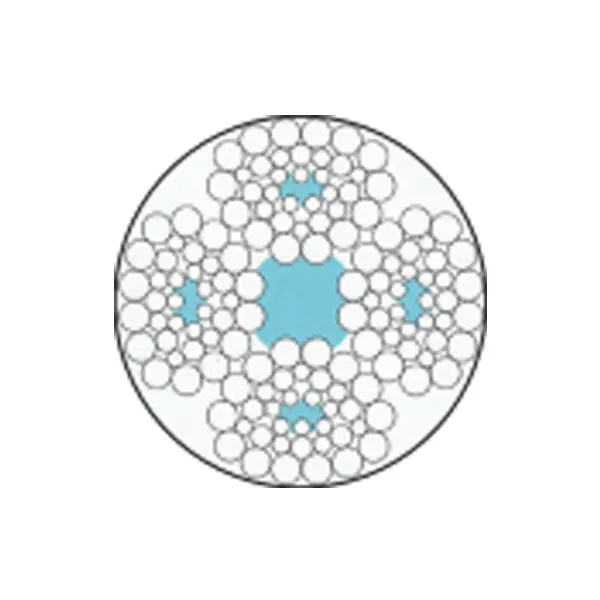

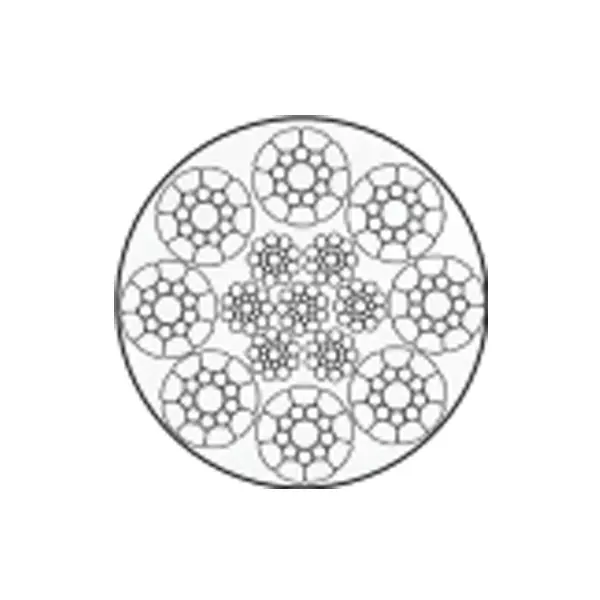

Materials and Structures

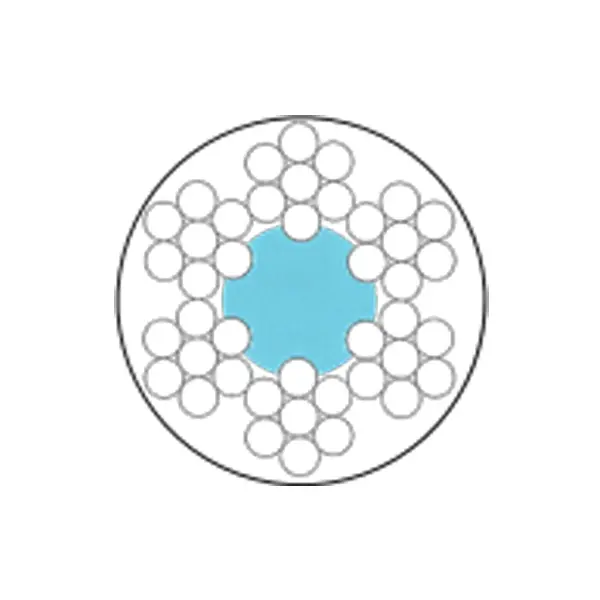

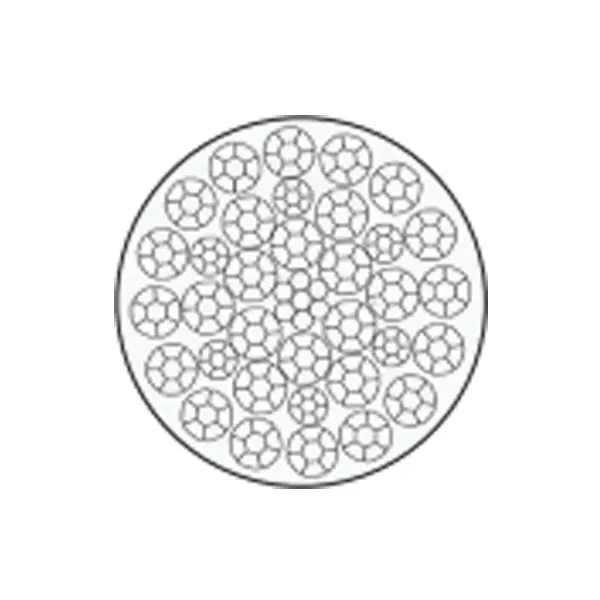

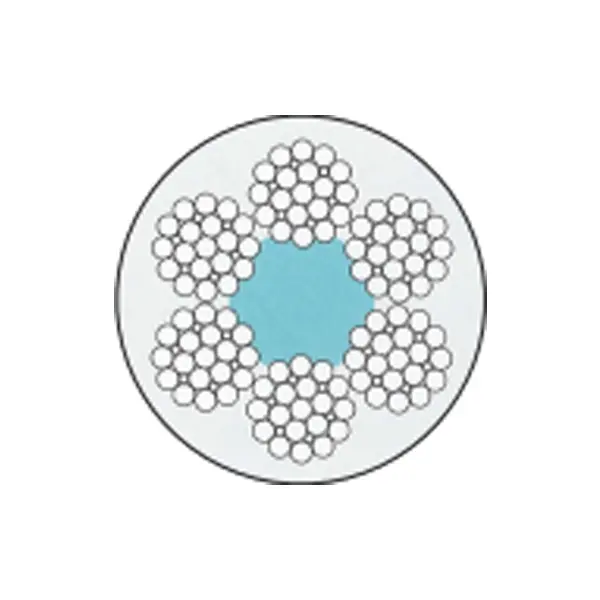

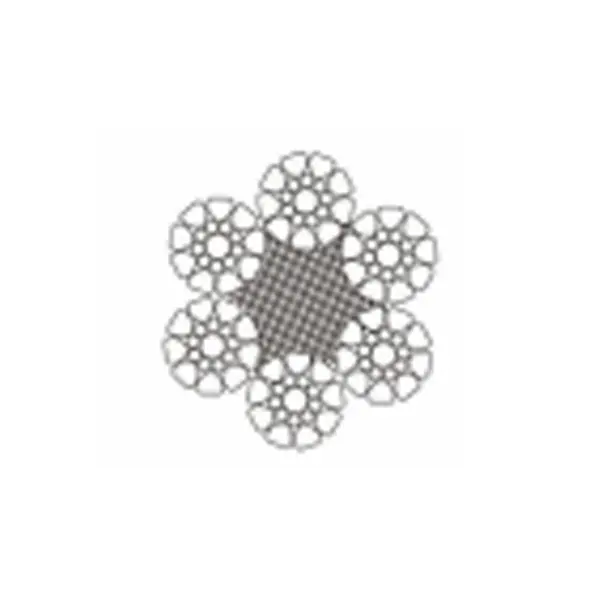

The net sleeve is usually made from high-strength steel wire rope, offering excellent tensile strength and toughness. Its carefully designed structure consists of multiple woven steel wire ropes forming a tight, elastic network. This structure wraps the cable effectively and evenly distributes the load, preventing stress concentration that could lead to wire breakage.

Flexibility and Coordination

The net sleeve boasts excellent flexibility, adapting to various cable shapes and routes. It adheres closely to the cable, whether being dragged straight, turning, or operating in complex environments. It also coordinates well with lifting equipment, such as cranes and hoists, ensuring a smooth and efficient cable lifting process.

Safety

The net sleeve provides reliable protection for the cable, preventing mechanical damage during lifting operations, such as collisions and friction. Its stable structure and high-strength material ensure the cable does not fall off during lifting, safeguarding personnel and equipment. This safety advantage is particularly significant in high-altitude and confined space operations, effectively reducing the risk of accidents.