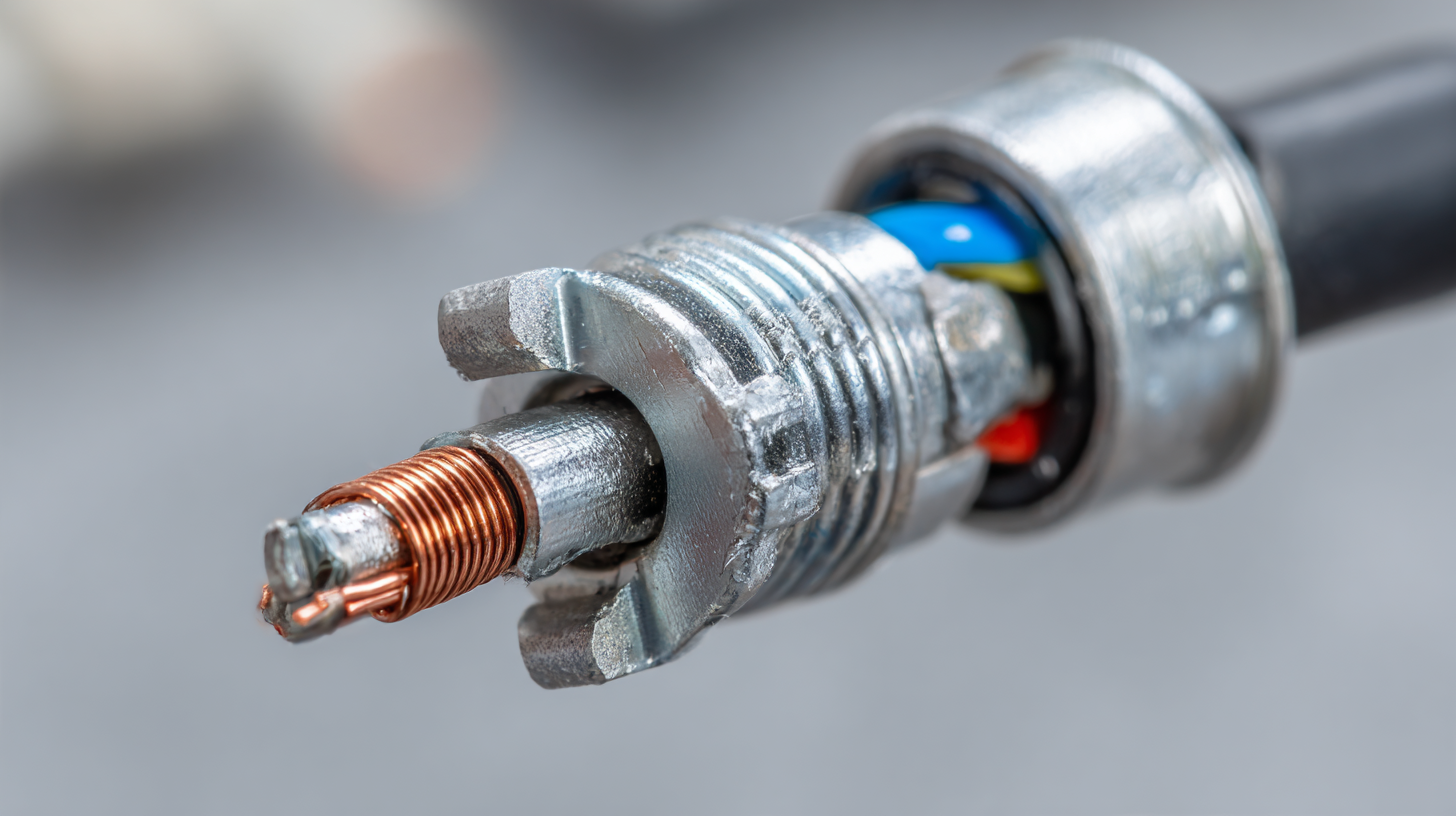

In the rapidly evolving landscape of electrical installations, safety and efficiency remain paramount. The use of innovative tools such as the Split Cord Grip has emerged as a critical factor in enhancing operational reliability across various sectors. According to a recent report by the National Electrical Contractors Association (NECA), nearly 30% of electrical project delays arise from safety-related incidents, highlighting the urgent need for improved protective measures. Additionally, studies show that effective cable management systems can boost productivity by up to 15%, underscoring the importance of seamless integration in wiring solutions. As industry standards advance, the Split Cord Grip stands out not only as a safeguard against wear and tear but also as a facilitator of streamlined workflows, ultimately paving the way for safer and more efficient electrical installations worldwide.

In the rapidly evolving landscape of electrical installations, safety and efficiency remain paramount. The use of innovative tools such as the Split Cord Grip has emerged as a critical factor in enhancing operational reliability across various sectors. According to a recent report by the National Electrical Contractors Association (NECA), nearly 30% of electrical project delays arise from safety-related incidents, highlighting the urgent need for improved protective measures. Additionally, studies show that effective cable management systems can boost productivity by up to 15%, underscoring the importance of seamless integration in wiring solutions. As industry standards advance, the Split Cord Grip stands out not only as a safeguard against wear and tear but also as a facilitator of streamlined workflows, ultimately paving the way for safer and more efficient electrical installations worldwide.

When discussing electrical safety in installations, the importance of a robust split cord grip cannot be overstated. An effective split cord grip not only secures electrical connections but also minimizes the risk of accidental disconnection, which can lead to hazardous situations. Industry reports indicate that improper securing of electrical connections accounts for approximately 20% of workplace electrical hazards. The right split cord grip should feature durable materials, such as high-quality nylon or thermoplastic elastomer, providing superior resistance to corrosion and wear over time.

In selecting a split cord grip, it’s essential to look for designs that offer strain relief. Effective strain relief prevents damaging tension on electrical cords, thereby reducing the likelihood of insulation damage or wire fatigue. A study by the International Electrotechnical Commission (IEC) highlights that products incorporating strain relief measures have a 30% lower failure rate than those without.

Tips for choosing the right split cord grip:

1. Ensure the grip can accommodate the specific cord size you are working with to ensure proper fit and quality performance.

2. Look for features that allow for quick installation and removal, making maintenance easier while ensuring safety.

3. Validate that the split cord grip complies with relevant safety standards, such as those established by Underwriters Laboratories (UL) or the National Fire Protection Association (NFPA), to guarantee reliability in critical applications.

When it comes to electrical installations, the quality of cord grips can significantly impact safety and efficiency. However, the effectiveness of these essential components is often heavily influenced by the reputation of their suppliers. A supplier with a strong track record is likely to deliver products that meet rigorous safety standards and performance criteria. This is particularly important because subpar cord grips can lead to hazardous situations, potentially endangering both equipment and personnel.

Choosing a reputable supplier not only ensures the delivery of high-quality cord grips but also fosters confidence in the reliability of the products used. Established suppliers typically offer products that comply with industry regulations and provide certifications that validate their quality. Moreover, they often have a history of customer satisfaction and support, which can be invaluable for professionals in the electrical field seeking reliable solutions for their installation projects. In an industry where safety is paramount, prioritizing suppliers with a solid reputation is crucial for ensuring safe and efficient results.

When selecting a split cord grip supplier, evaluating material durability is crucial for ensuring long-term safety and performance in electrical installations. The materials used in cord grips directly affect their ability to withstand various environmental factors such as temperature fluctuations, moisture, and mechanical stress. High-quality materials like stainless steel or advanced polymers can provide superior resistance to corrosion, wear, and tear, ensuring that the cord grips maintain their integrity over time. A thorough examination of material specifications and certifications can help identify suppliers who prioritize durability in their product offerings.

In addition to material selection, consider the supplier’s testing and quality assurance processes. Reliable suppliers often adhere to industry standards and have rigorous testing protocols in place to assess the resilience of their products under different conditions. Inquire about the lifespan of the products, as well as any warranties offered, as these factors can provide valuable insight into a supplier’s confidence in the durability of their split cord grips. Ultimately, choosing a reputable supplier with a strong focus on material durability will enhance both safety and efficiency in electrical installations globally.

When selecting a split cord grip for electrical installations, it’s crucial to consider both performance and cost-effectiveness. Comparing prices and specifications from multiple suppliers can be daunting, but with the right approach, you can make an informed decision. Start by gathering information from at least three different manufacturers to understand the range of products available. Pay close attention to the materials used in the cord grips, as higher-quality materials often justify a higher price due to enhanced durability and safety features.

Another tip is to check for compliance with industry standards. Ensure that the suppliers you consider provide certifications that demonstrate their products adhere to relevant safety regulations. This not only impacts the overall safety of your electrical installations but can also save costs in the long run, avoiding potential fines or rework caused by non-compliance. Additionally, don't hesitate to request samples or detailed specifications. Testing different cord grips firsthand can help you assess their performance and compatibility with your specific installations.

| Specification | Value | Supplier A | Supplier B | Supplier C |

|---|---|---|---|---|

| Material | Polymer | Polymer | Rubber | Polymer |

| Temperature Resistance | -40°C to 100°C | -25°C to 80°C | -40°C to 90°C | -40°C to 100°C |

| Max Load Capacity | 15A | 10A | 15A | 15A |

| Water Resistance Rating | IP65 | IP54 | IP67 | IP65 |

| Price | $2.50 | $2.00 | $3.00 | $2.80 |

When it comes to ensuring safety and efficiency in electrical installations, verifying supplier standards for electrical products is paramount. Industries around the globe rely on compliance with safety regulations, such as those set by occupational safety bodies, to mitigate risks. A recent update to the OSHA compliance checklist emphasizes the importance of assessing supplier adherence to safety standards, ensuring that products not only meet performance expectations but also safeguard workers' health.

To support this compliance, a strategy for assessing electrical products includes verifying that they are featured on approved lists, like those maintained for solar PV modules and batteries that align with national standards. This reinforces the integrity of the supply chain, enabling businesses to manage risks associated with non-compliant products.

**Tips:**

- Always check if your supplier's products are certified and listed on recognized approval lists.

- Conduct regular audits of your suppliers to ensure ongoing compliance with industry standards.

- Stay informed about regulatory updates, such as those from labor and safety organizations, to keep your operations compliant and safe.