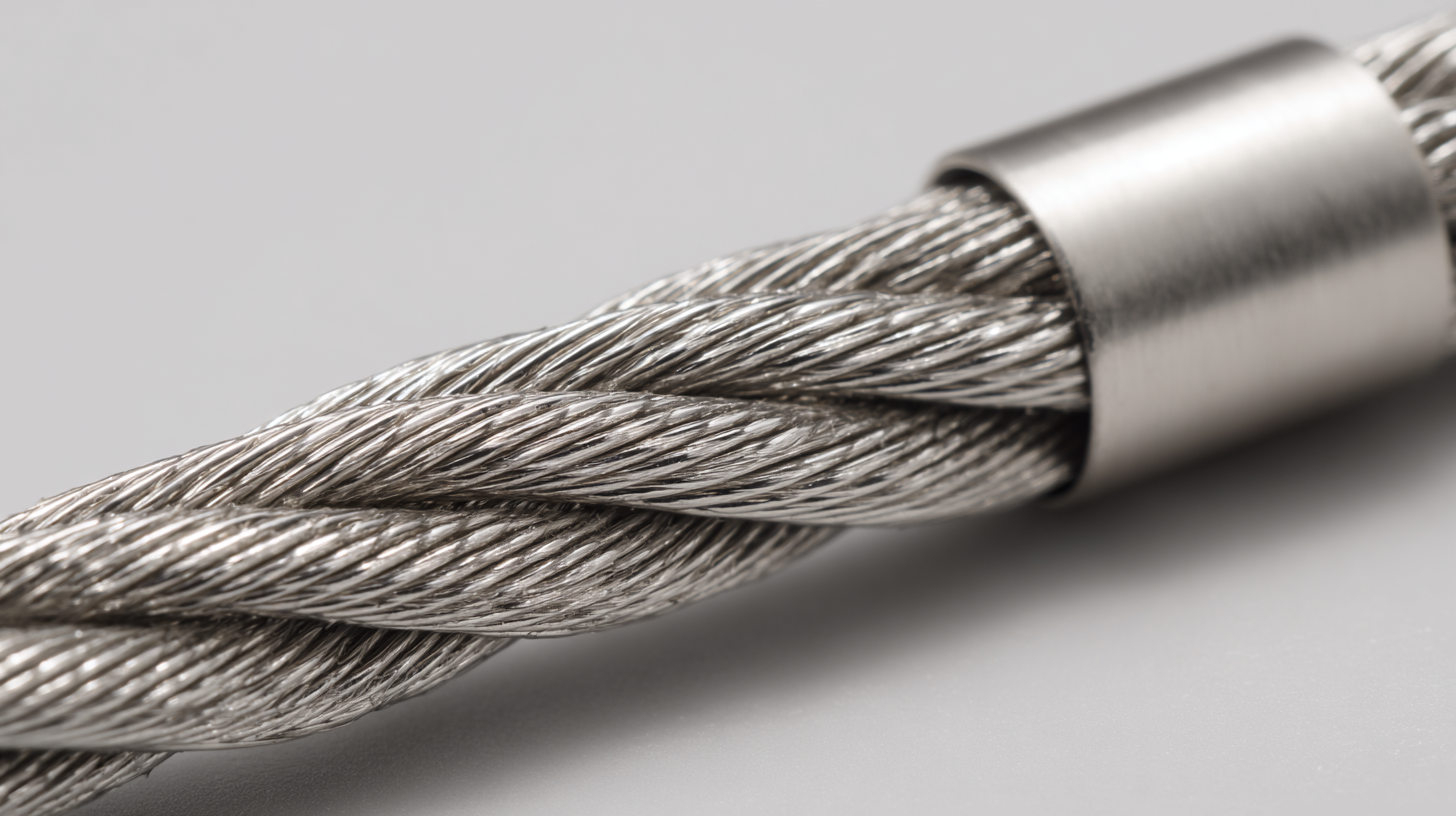

In today's rapidly evolving industrial landscape, the use of Stainless Steel Cord Grips has emerged as a pivotal component in enhancing both safety and efficiency across various applications. According to a report by the Global Market Insights, the demand for stainless steel components in industrial settings is projected to witness a growth rate of over 5% annually through 2025, driven by the increasing need for durability and resistance to corrosive environments. Stainless Steel Cord Grips, known for their robust construction and versatility, play a crucial role in securing cables and conduits, thereby minimizing the risk of wear and tear. As industries prioritize compliance with stringent safety standards and operational longevity, these corrosion-resistant solutions not only provide mechanical protection but also enhance the aesthetic appeal of installations. This article delves into the myriad benefits of integrating Stainless Steel Cord Grips into modern applications, showcasing their significance in ensuring both functionality and reliability.

Stainless steel cord grips offer significant advantages in industrial settings, particularly due to their durability and resistance to environmental factors. According to industry reports, stainless steel components can withstand extreme temperatures and corrosive conditions, making them ideal for applications in manufacturing and outdoor installations. For instance, a study by the International Stainless Steel Forum indicates that stainless steel has a corrosion resistance coefficient that is three to five times higher than that of carbon steel, leading to a longer lifespan and reduced maintenance costs.

When selecting cord grips for industrial use, consider the environmental conditions they will face. **Tip:** Always choose cord grips with a higher grade of stainless steel, such as 316, for areas exposed to harsh chemicals or saline environments. Additionally, the design of these grips allows for easy installation and strain relief, ensuring that electrical cords and wires remain secure and free from damage.

Another key benefit is the versatility of stainless steel cord grips. Reports show that industries ranging from telecommunications to aerospace utilize these components for various applications, owing to their reliable performance. **Tip:** Regularly inspect cord grips for any signs of wear, particularly in high-stress environments, to ensure consistent functionality and safety in your operations.

Stainless steel cord grips have gained considerable attention in modern applications due to their exceptional durability and resilience. The material's resistance to corrosion and extreme temperatures makes it an ideal choice for various industries, including construction, automotive, and electrical systems. The ability to withstand harsh environmental conditions while maintaining structural integrity is a testament to the advantages of stainless steel usage.

In the context of recent studies examining the bearing strength of composite materials, the resilience of stainless steel can be particularly beneficial. When utilized in conjunction with other materials, such as GFRP (Glass Fiber Reinforced Polymer), stainless steel cord grips can enhance overall performance by providing stable support and reducing the risk of material delamination. This synergy not only improves the lifespan of applications but also ensures safety and reliability in demanding environments.

**Tips:** When selecting stainless steel cord grips, consider the specific conditions they will face, such as exposure to chemicals or extreme weather. Additionally, ensure proper installation and maintenance to maximize their benefits. Regular inspection can help identify wear or degradation early, extending the lifespan of both the grips and the overall system they support.

Stainless steel cord grips are increasingly favored in modern applications due to their exceptional corrosion resistance. Unlike traditional materials that may degrade in harsh environments, stainless steel maintains its integrity when exposed to moisture, chemicals, and extreme temperatures. This durability not only ensures longevity but also reduces maintenance costs, making it a practical choice for industries such as marine, construction, and manufacturing.

The superiority of stainless steel lies in its composition, which includes chromium, providing a protective layer that prevents rust and corrosion. This characteristic is especially critical in applications where equipment and components are subjected to unfavorable conditions, such as saltwater exposure or chemical environments. By investing in stainless steel cord grips, companies can enhance the reliability of their systems while minimizing the risks associated with equipment failure due to corrosion, ultimately leading to increased safety and efficiency in operations.

When considering the cost-efficiency of stainless steel cord grips in modern applications, it’s essential to recognize their longevity and robustness. According to a report by MarketsandMarkets, the global stainless steel market is expected to grow significantly, driven by the demand for durable materials in various industries. Stainless steel cord grips not only resist corrosion but also require minimal maintenance over their lifespan, resulting in substantial cost savings. Industries that utilize these components often report a reduction in replacement and repair expenses, translating into lower overall operational costs.

**Tips:** When selecting stainless steel cord grips for your application, always consider the workload and environmental conditions to ensure you choose the right specifications. Additionally, standardized products are often more cost-effective, so opt for sizes and types that are commonly used in your industry.

Investing in high-quality stainless steel cord grips means fewer disruptions due to equipment failures. A recent study indicated that companies that switch to high-performance materials like stainless steel experience a 15-20% reduction in system downtime. This not only boosts efficiency but also enhances the bottom line, making stainless steel cord grips a smart choice for any modern application looking to maintain cost-efficiency in the long run.

| Application Area | Cost of Stainless Steel Cord Grip (USD) | Longevity (Years) | Maintenance Cost (Annual USD) | Total Cost Over 10 Years (USD) |

|---|---|---|---|---|

| Electrical Installations | $10 | 15 | $50 | $550 |

| Industrial Machinery | $15 | 20 | $75 | $1,275 |

| Telecommunications | $12 | 10 | $40 | $520 |

| Construction | $20 | 25 | $100 | $2,500 |

| Aerospace | $25 | 30 | $150 | $4,800 |

Stainless steel cord grips have gained significant traction across various industries due to their exceptional versatility and robustness. In the electrical industry, for instance, these cord grips are essential components that ensure secure cable management. According to a report by MarketsandMarkets, the global cord grip market is projected to reach USD 578 million by 2025, underscoring the increasing demand for reliable cable accessories that can withstand environmental and mechanical stress. The corrosion-resistant properties of stainless steel make these grips ideal for outdoor installations, where they can endure harsh weather conditions without compromising performance.

In the automotive sector, stainless steel cord grips play a crucial role in maintaining the integrity of wiring harnesses and electrical connections. They provide strain relief and prevent cable damage, which is vital for vehicle safety and longevity. A study published in the Journal of Materials Science & Engineering highlighted that stainless steel offers a tensile strength at least three times greater than traditional materials used in cord grips. This durability is particularly important in high-performance vehicles, where the risk of component failure can have serious safety implications. As industries continue to evolve in terms of technology and environmental demands, the adaptability of stainless steel cord grips will remain essential in ensuring operational efficiency and safety.